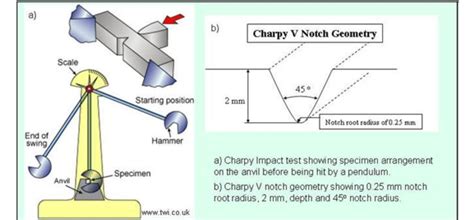

charpy impact test notch angle|charpy v notch testing standard : wholesaling Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be : V-notch – A V-shaped notch, 2mm deep, with 45° .

4 de mar. de 2023 · Likes Received: 14,412. Trophy Points: 1,672. (Update: PS3HEN 3.2.0 w/ 4.90 Support Released) Exploiting a PlayStation 3 console in firmware 4.89 was a bit .

{plog:ftitle_list}

Resultado da 24 de abr. de 2023 · Sires Produce Stakes 2024 field, tips, betting odds, past winners and results. The Sires Produce Stakes is run on March 9th, 2024 at a distance of 1400m at the Flemington Racecourse.

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test .

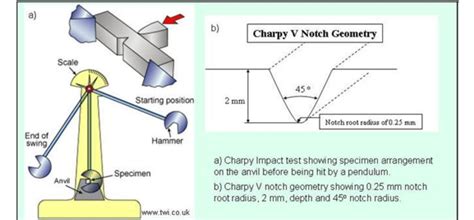

The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .The Charpy impact specimens of each material are immersed in a bath for 10 minutes to reach thermal equilibrium at five separate temperatures ranging from -110oF (-79oC) to 212oF . The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture. The .

Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be : V-notch – A V-shaped notch, 2mm deep, with 45° . Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be: • V-notch – A V-shaped notch, 2mm deep, with 45° angle and 0.25mm radius along the .

charpy v notch toughness

In the Charpy impact test, a notched specimen is abruptly subjected to bending stress. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm. The notch in the middle has a V-shaped .The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps .Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step .

The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. . A V-shaped notch, 2mm deep, with 45° angle and 0.25mm radius along the base. U-notch or keyhole notch – A 5mm deep notch with 1mm radius at the base of the notch. Fig 2 .The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient . The low-velocity impact behavior of hybrid composite laminates was investigated. The epoxy matrix was reinforced with aramid, glass, basalt, and carbon fabrics using the hand lay-up technique. Different stacking sequences and notch angles were and notch angles considered and tested using a Charpy impact testing machine to study the hybridization and . The Charpy Impact Test, also known as the Charpy V-notch test, is a crucial method in the field of materials testing. This test helps determine a material’s ability to absorb energy and resist breakage under high-velocity impacts. . Notch Angle: Typically 45 degrees in accordance with ASTM E23 for metals. Notch Radius: 0.25 mm as per the .

ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the fracture behavior changes as the temperature drops and the fracture type changes from ductility to brittleness.

Scope: This standard specifies the requirements for notched-bar impact testing using both Charpy and Izod methods. It includes guidelines for specimen dimensions, preparation, and testing procedures. . 10 mm thickness, with a 2 mm deep notch and a 45° angle. Charpy U-Notch: 55 mm length, 10 mm width, 10 mm thickness, with a 1 mm radius . The “standard” notch used in the Charpy impact test is the 2 mm deep V-notch with a 0.25 mm root radius, but other geometries are or have been sometimes used. Depending on notch geometry, the test is known as the Charpy-V impact test (CVN) or Charpy-U impact test (CUN) or even Charpy-keyhole. The U-notch has normally a radius of 1 mm.IS:1757-1988 4. Test Pieces 4.1 The standard test piece shall be 55 mm long and of square section with 10 each side.In the centre of the length there shall be a V-notch of 45” included angle, 2 mm deep, with 0’25 mm rootCharpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).

In the present study Charpy impact tests on a 7075-T651 aluminium alloy with full size (55×10×10 mm) with different notch tip radius (range of 0.19 to 0.40 mm) were conducted and the fracture . Steel-Charpy Impact Test ( U-Notch ). Assistance has also been derived from BS 131: Part 3 : 1972 Methods for notched bar tests: Part 3 The charpy U-notch impact test on metals. 0.3 The revision: a) b) c) following major modifications have been incorporated in this

Charpy impact test was developed in the 1960's as a method of determining the relative impact strength of . mm in width and 55 mm in length and a V-shaped notch, 2mm deep, with 45° angle and 0.25mm radius along the base and specimen is fabricated (as required in the ISO 179/ASTM E23) is used for the finite element analysis. .Plastics—Verification of pendulum impact-testing machines—Charpy, Izod and tensile impact-testing: ASTM: D6110: Charpy: Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of .By testing plastics with the Charpy , IZOD test method the impact resistance of the plastic can be determined. Charpy and IZOD impact testing machine testercan also be used to determine the sensitivity of notched plastics specimens. . Impact blade angle radius: R=2mm: Izod Impact Test : Impact energy: 1J, 2.72J, 5.5J: 5.5J, 11J, 22J: 1J, 2 .Charpy impact test method for metallic materials is specified by European EN 10045 standard. . and tolerances in height are 0.11 mm for U and 0.06 mm for V notch test piece. Tolerances for angle between plane of symmetry of the .

The standard Charpy Impact Test specimen consist of a bar of metal, or other material, 55x10x10mm having a notch machined across one of the larger dimensions. V-notch: 2mm deep, with 45° angle and 0.25mm radius along the base; U-notch and keyhole notch: 5mm deep notch with 1mm radius at base of notch; The Charpy Impact Test consist of striking .

Different factors such as notch angle, notch depth, notch root radius, specimen size, hammer . Charpy impact testing was performed using a 750 J Zwicktestingmachineat20°C.Toobtainthemeanfrac-The Charpy impact specimens of each material are immersed in a bath for 10 minu tes to reach thermal equilibrium at five separate temperatures ranging from 110oF (-79oC) to 212-oF (100oC). The specimens are quickly transferred to the Charpy testing machine, fractured, and the impact energy is measured. After

Angle between plane of symmetry of notch . RELEVANT INDIAN STANDARD FOR CHARPY IMPACT TEST: IS 1598:1977-Method for Izod impact test of metals; IS:3766-1977- Method for calibration of pendulum impact testing machines for testing metals; Community Links Sakshat Portal Outreach Portal FAQ: Virtual Labs.CHARPY IMPACT TEST ISO 179 Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. The values recorded can be used for quality

Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.

Izod impact tester in Blists Hill Victorian Town. The Izod impact strength test is an ASTM standard method of determining the impact resistance of materials. A pivoting arm is raised to a specific height (constant potential energy) and then released.The arm swings down hitting a notched sample, breaking the specimen. The energy absorbed by the sample is calculated .

In this paper the influence of notch acuity and test temperature on the impact behavior of aluminum alloy 6061 is presented and discussed. Notch angles of 45°, 60°, 75° and 90° were chosen for a standard charpy impact test specimen containing two such notches positioned at right angles to the applied load. For a given angle of the notch the dynamic fracture .Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.

charpy v notch testing standard

E-mail customer support: General & Sportsbook: bet@everyg.

charpy impact test notch angle|charpy v notch testing standard